Introduction to TDF Flange Forming Machine

Aug 12, 2024

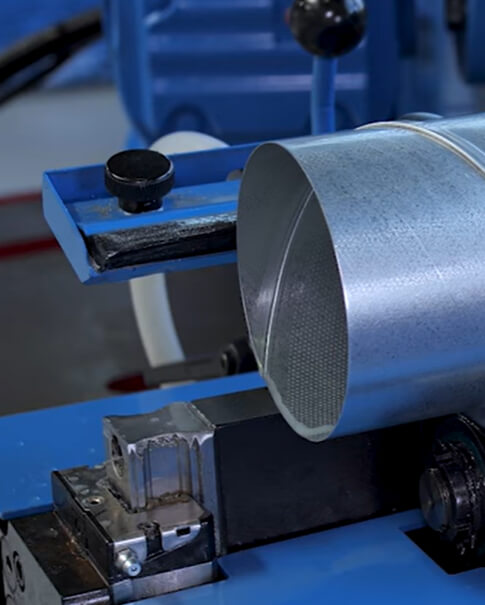

TDF Flange Forming Machine is a molding equipment specially used to make common plate flanges (also known as flangeless air ducts). This flange system is especially suitable for ventilation ducts with small cross-sectional areas. The following is a detailed introduction to the TDF common plate flange machine:

1.Features and advantages

(1)Low cost: The air duct connection port made by the TDF Flange Forming Machine adopts direct bite or intermediate piece bite. Compared with the traditional flange connection, the material cost of the flange and accessories is saved.

(2)Good sealing performance: The sealing performance of the air duct without flange connection is better than that of traditional flange connection, reducing the air leakage rate.

(3)Simple installation: No complicated installation process of flanges and accessories is required, which simplifies the construction process and improves installation efficiency.

(4)Wide scope of application: Especially suitable for the production of small air duct factories, and also suitable for the needs of markets such as East Asia, Australia and the Americas.

2.Technical parameters

According to publicly released information, the technical parameters of TDF Flange Forming Machines may include but are not limited to the following (taking a certain model as an example):

(1)Model: T-12

(2)Plate thickness: flange 0.4-1.2 MM, card code 1.0-1.2MM

(3)Material: galvanized steel plate

(4)Material strength: ≤235MPa

(5)Line speed: 8M/MIN

(6)Roller material: 40CR (or 45# steel, GR15, etc., specific materials may vary depending on the manufacturer)

(7)Forming passes: 21 passes

(8)Forming station: The standard station is used to make TDF flanges, and the auxiliary station is used to make flange card codes.

(9)Equipped with: 15 pairs of forming rollers

3.Application scenarios

TDF Flange Forming Machines are widely used in central air conditioning ventilation systems, industrial plant ventilation, commercial building ventilation and other fields. With the increasing requirements for energy conservation and environmental protection, flangeless air ducts have gradually become the mainstream in the market due to their excellent sealing performance and lower cost.

4. Combined use

The TDF Flange Forming Machine can be combined with a seaming machine, a beading machine, a shearing machine, a folding machine, etc. to form a simple or fully automatic air duct production line. This combination not only improves production efficiency, but also saves costs and reduces expenses for customers.

5. Market and Prospects

With the global emphasis on energy conservation, environmental protection and sustainable development, as well as the rapid development of the construction industry, the market demand for TDF Flange Forming Machines continues to grow. Especially in markets such as East Asia, Australia and America, TDF common plate flange machines have been widely welcomed due to their exquisite appearance and excellent performance.

In summary, the TDF Flange Forming Machine is an efficient and low-cost air duct production equipment with broad market prospects and application space.